By Gemma Carroll, Communications & Engagement Officer, PNZ.

Meet Chris Thorman.

He’s a Potato Storage enthusiast with 30 years of experience in New Zealand and the UK.

He works as Program Coordinator for the Post-Harvest Diploma, at Eastern Institute of Technology and he lectures in Crop Protection and other related subjects.

Chris has been in the potato industry for over 30 years, the bulk of his time has been in Scotland, working with farmers & small businesses, specialising in seed potato production .

Chris started as a fieldsman for Howard England Ltd and Strathearn Seed Growers Ltd, with around 40 growers, in a seed potato growing operation and production contracting. He worked his way up to the role of Director and was then part of a management buy-out. The business contracted approximately 15,000 tonne of seed potatoes annually to the processing sector, including McCain’s crops of Russet Burbank and Pentland Dell, and Record, Hermes and Saturna for Walkers and Smiths Crisps. Eventually this led Chris to storage specialisation.

In 1989 Pepsico took over both the crisps companies and required seed production to focus on tuber disease, due to it’s effects on quality. In 1989 skin spot disease had hit record highs, as it reacted with choloropropham (CIPC), a commonly used sprout inhibitor, and was blamed for deeper lesions on the tubers, affecting the peeling process. The outcome of this problem was higher costs, excessive tissue loss, and uneven colours on the crisps. It was estimated to cost $1 million pounds per year in loss.

As Chris was already the link between English growers & Scottish seed growers, he then worked with a team of people from PFI, Twygen, Rothamstead, SCRI and SAC to investigate the problem and come up with a practical solution.

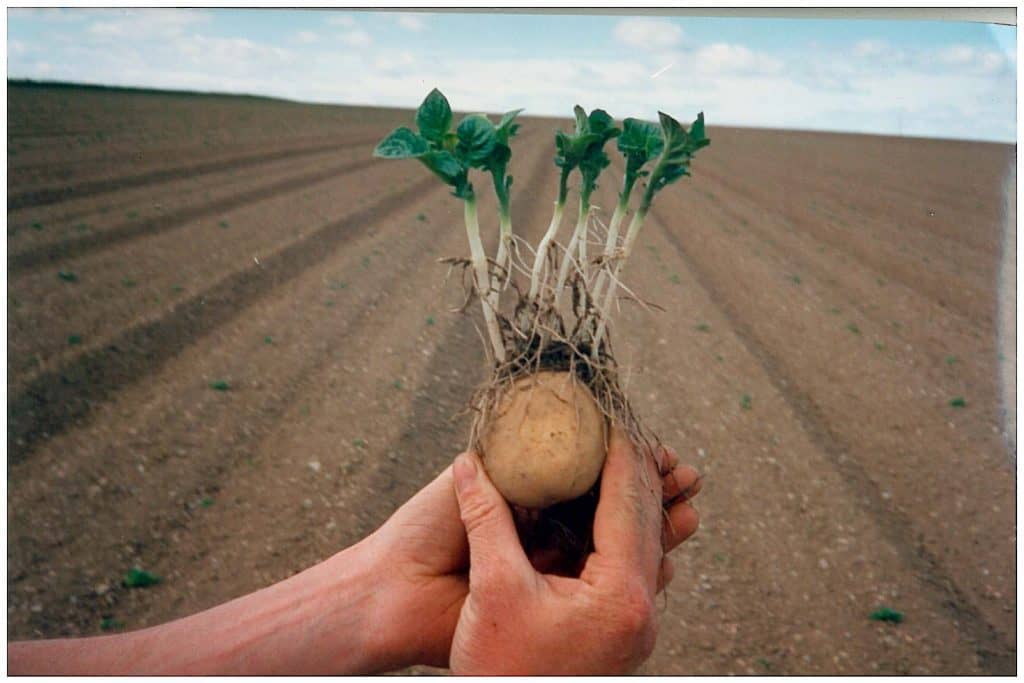

Scotland had developed the VTSC (virus tested stem cuttings) system to produce high health plants for the seed multiplication process. The process started with clones of small numbers of virus free tubers, however the system did not address the tuber diseases issues and every field generation increases both virus and tuber disease potential.

“The VTSC system produced heathy plants and by careful crop management, crops can be kept largely virus free over several multiplication generations, however this is not the case for the tuber diseases, and it’s the tubers we sell. Disease on the surface of the tuber causes economic loss through grade out”.

Disease is only an economic loss when it turns into the visual form of the disease – spores on the surface are not a problem per say. “If you can reduce the spore contamination, you can reduce the risk of tuber disease during the multiplication process.”

“The reality is, there’s not a lot we can do to protect daughter tubers in the soil, apart from planting treatments. However, when we harvest the crop, we can have processes that reduce potential disease loading and the storage regime can massively influence the potential for disease development on the tuber.”

Chris helped establish a grow group based around set protocols for the storage and handling of seed potatoes, most of which is transferable to general commercial potato storage.

Each grower was evaluated individually and invited to join if they met the overall objectives of the group. Conditions and requirements varied from grower to grower, but the underlying protocol remained the same.

The group would only produce limited field generation seed in three field generations. That meant planting over 300,000 first field generation mini tubers each year at a cost of 95 pence each (over NZ $3 at that time).

Harvesting and storage would follow Good Seed Potatoes Practice and a protocol was developed that the growers could modify their systems to achieve. The aim was to produce seed with low disease loading. The U.K. group and the protocol still underpin storage practice today, 30 years on, and they now have a significant export business.

So what did Chris learn in the UK that can be applied in NZ?

Using his experience, Chris has been involved in storage upgrades for growers both in Scotland and in New Zealand, working with storage specialists Farm Electronics, and designing and developing over 50 stores for a range of seed, table and processing growers.

All of the UK processes are applicable to New Zealand growers, as long as NZ conditions are accounted for.

The main challenge for storage in New Zealand is simply ensuring growers are well informed. The old kiwi adage “she’ll be right” is no longer suffice. As the market requirements increase in all areas of production, the risks of crop failure need to be further mitigated. We will all to soon be facing compliance pressures in storage. These pressures are coming from both the consumer and regulatory bodies. We need to stay ahead of the game. It’s always useful to review and assess where businesses can improve.

The solution lies in looking at individual grower production processes. We need to analyse the handling and storage systems, in light of the latest research.

We need to make every tonne count and minimise post-harvest losses.

- Each grower would benefit by doing a self-evaluation – including moisture loss eg: weight before and after storage.

Eg: In Scotland a grower weighed every bin he put into his store, totaling 1133 tonnes. He then weighed output of the store, after 5 months of storage. His saleable yield was 940 tonnes of seed. He’d lost 16 tonnes of sprouts and 44 tonnes of soil and grade outs. The overall weight loss was 149 tonnes or 13%. This was mostly due to limited air flow and no temp control. The grower upgraded his storage, based on the proposed protocol and one year later, the weight loss was reduced to 7%.

Ask yourself: What % marketable yield am I losing? What is that worth in dollars? What if I could halve that loss? - PNZ are planning workshops for 2020 to facilitate assessing your potato production process – from burn-off to delivery. In these workshops we will discuss the latest research, look at disease physiology, examine best practice and growers will evaluate their postharvest practice against a protocol. No one system is right, and there are many factors to take into account, but the aim is to place a spot light on storage and allow growers to look for focus points, that will help decide on where, when and how improvements can be made.

Fast Facts

Current risks: disease, sprouting & marketable yield loss

Solution: individual evaluations, education on overall concept of storage and potential problems and developing a protocol for your business.

All this and more will be covered by Chris Thorman & Allan Greenhalgh (TOLSMA GRISNICH) at our biennial conference, 13th-14th August 2019, Christchurch.

Register online https://conference.potatoesnz.co.nz/delegate-registration/